+86 769-8634 1972

+86 136-0028-3195

+86 136-0028-3195

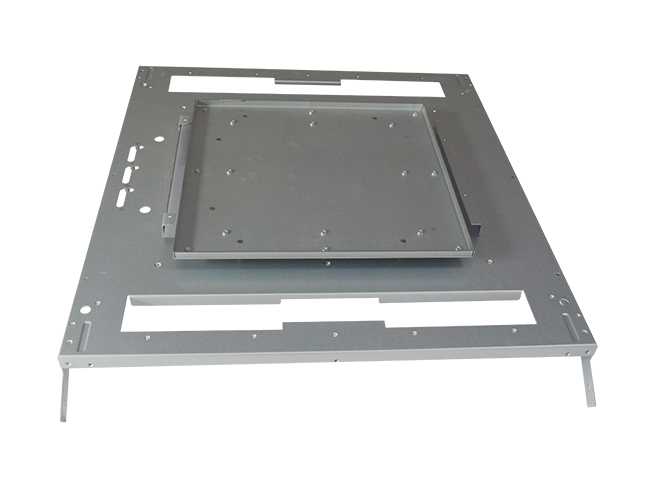

Spray plastic is often used in sheet metal processing, so that the surface of the workpiece is beautiful and generous, rust prevention. The raw material plastic powder for spraying applications is actually thermosetting powder coating, which has risen as an environmentally friendly coating with excellent performance, low pollution, less pollution and energy saving, and has become one of the main products to replace traditional solvent-based coatings.

The advantages of spraying the surface treatment of the workpiece in sheet metal processing:

1, the painting process saves the process, reduces the production cycle, generally only one spray, the thickness is 30 ~ 500 microns.

2, compared with the paint used in spray painting, plastic powder is non-flammable and explosive, and no volatile substances, so there is no need for ventilation and cooling equipment.

3, powder coating has a good edge penetration rate, there will be no flow hanging and dew bottom situation.

4, the thermosetting powder coating after curing has high tensile strength, the coated workpiece needs to be greatly reduced during transportation and assembly, and the coating coating can also be carried out mechanical processing and manufacturing.

5, suitable for automatic spraying equipment production line, you can achieve automatic coating film regulation of the coating.