+86 769-8634 1972

+86 136-0028-3195

+86 136-0028-3195

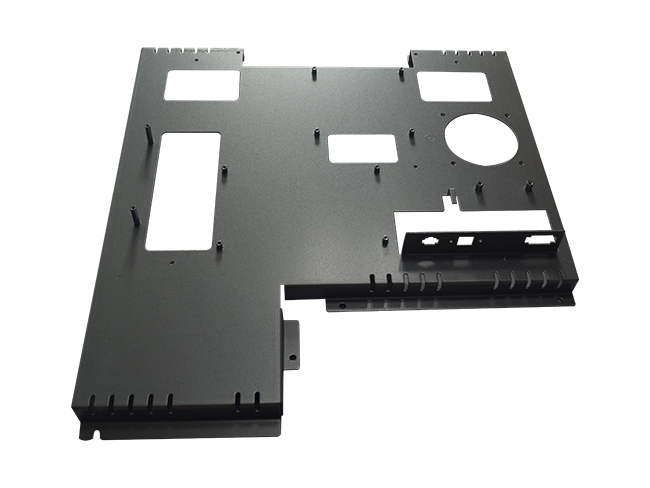

One of the most typical automatic sheet metal processing lines, mainly including warehouse, fiber laser cutting, automatic feeding and its robot sheet metal bending module, but these processes are indispensable handling, the installation of electric permanent magnet permanent magnet jack on the stamping robot can accelerate the work process, high quality and efficient!

Work flow:

1. Warehouse feeding - the operator uses the plover or forklift truck to transport the raw materials to the palletizer, and the palletizer will transport the plates into the warehouse. Raw material delivery - The electrodynamic raw material station takes out the whole sheet from the warehouse according to the production needs.

2. Feeding - the loading and unloading robot electric permanent magnet sucker moves to the laser feeding area to absorb the plate, and then sends the plate to the fiber laser cutting exchange table, the Z axis is moved to the safety place, and the fiber laser cutting begins to work.

3. Cutting -- After cutting the plate, the loading and unloading robot is moved above the operating table, and the electric permanent magnet permanent magnet jack is installed below the mechanical arm to absorb the finished plate and transport it to the electric trolley to ensure the integrity of the finished product.

4. Sorting and transferring - After the manual elimination of waste, the mechanical flashlight permanent magnet sucker is attached to the automatic cutting machine and quickly turned over and transported to the sheet metal bending module feeding area.

5. Automatic sheet metal bending -- the robot electric permanent magnet robot arm climbs the cutting parts from the electric trolley, automatically bends the sheet metal according to the set procedure, and then piles the material on the tray after the end.

In order to meet the individual needs of customers, the uniqueness of the product workpiece, according to the processing technology configuration of electric permanent magnet permanent magnet jack, can not ensure the accuracy of the product workpiece at the same time, safety available!